Product classification

Unshaped refractories for blast furnaces and hot blast stoves

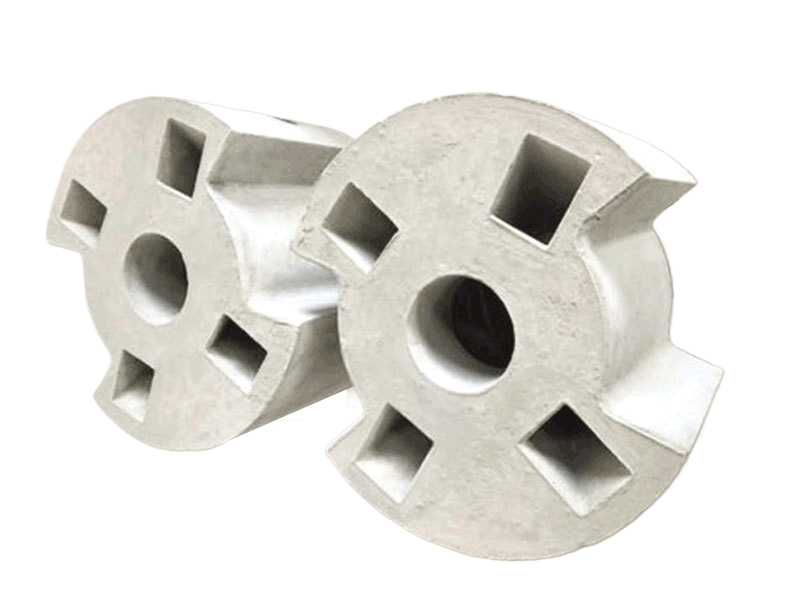

Our company research and development of SC series press into the material is divided into two series of water and no water. This series of press-in materials have good fluidity and can be well filled in the gap between the blast furnace shell and the cooling wall and repair the damaged parts of the furnace lining, so as to protect the furnace lining and prolong the service life of the blast furnace lining.

hiddenValue

Details Introduction

Our company research and development of SC series press into the material is divided into two series of water and no water. This series of press-in materials have good fluidity and can be well filled in the gap between the blast furnace shell and the cooling wall and repair the damaged parts of the furnace lining, so as to protect the furnace lining and prolong the service life of the blast furnace lining.

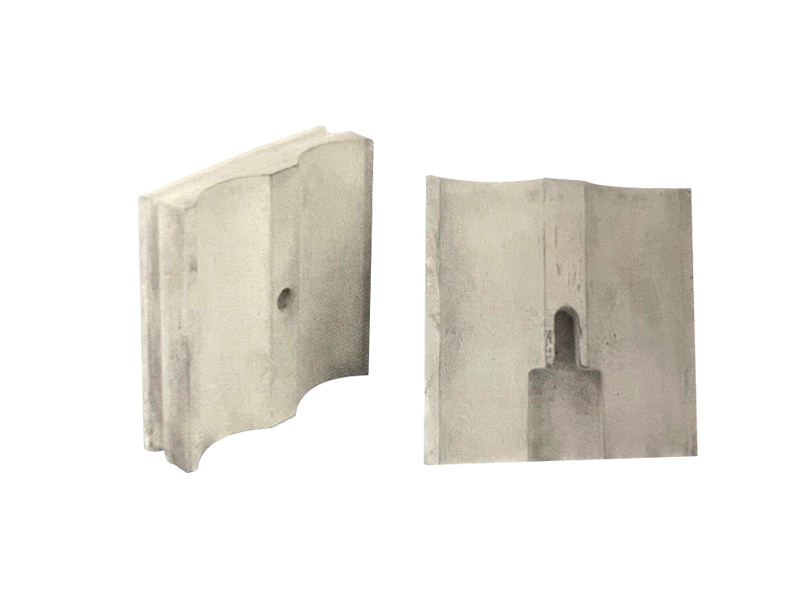

The unshaped refractory materials used in the hot blast stove body include dense castable, ramming material, light castable and spray paint. The ceramic burner prefabricated with HGR-H castable has superior resistance to airflow erosion and chemical erosion, and has been popularized and used in more than a dozen iron and steel companies across the country with good results. The vault of the hot blast stove is pounded with SiC filler, which is easy to be pounded and compacted, and has strong thermal conductivity. CH castable has the characteristics of high strength, low thermal conductivity and good thermal shock stability, which is suitable for the lining of air supply branch pipe and hot air valve.

Key words:

Unshaped refractories for blast furnaces and hot blast stoves

Product inquiry

Note: Please leave your phone number or E-mail and our professionals will contact you as soon as possible!

Related Products