Product classification

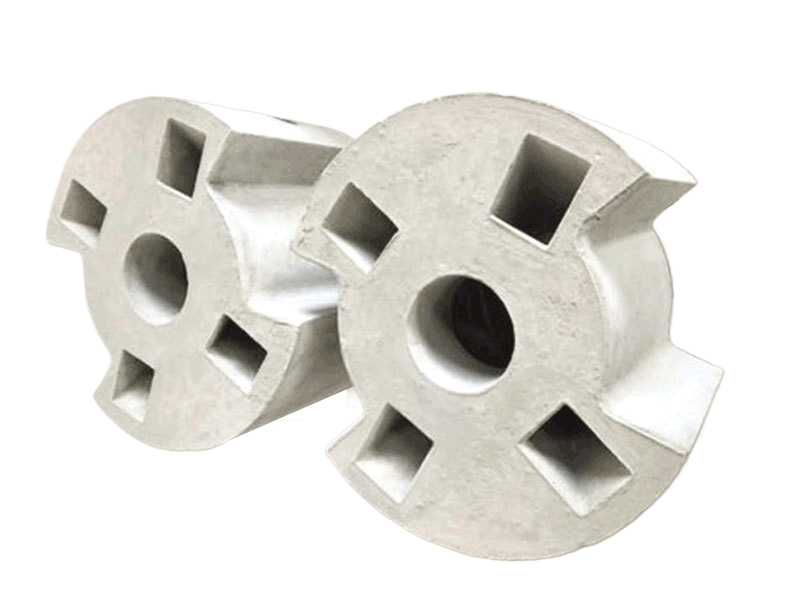

Impervious castable

hiddenValue

Details Introduction

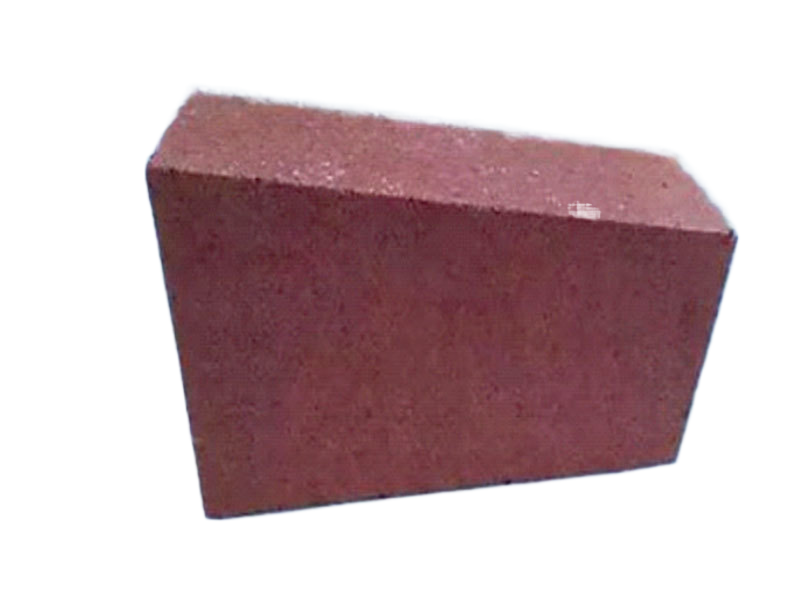

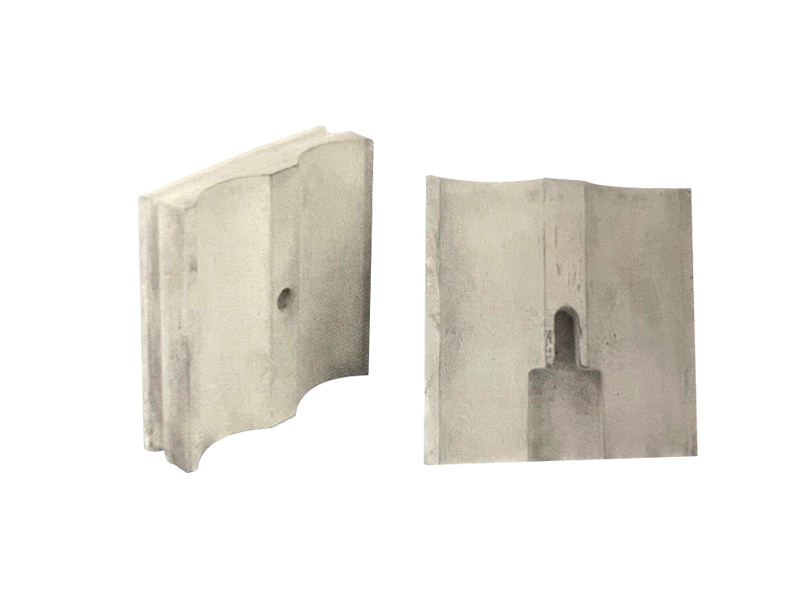

According to the different parts of the aluminum melting furnace, the corresponding refractory materials are selected. The load on the furnace roof is small, requiring good integrity and peeling resistance. The furnace wall that does not contact the aluminum liquid must bear a certain load. Low cement castables with alumina content above 60% are usually used in the furnace roof and furnace walls. The bottom part of the furnace that contacts the aluminum liquid requires that the porosity of the refractory material is low, and it does not wet with the aluminum solution and does not react. The furnace bottom and the molten pool are the key to determine the life of the whole furnace. Using high quality high bauxite, corundum, silicon carbide as the main raw material, control the free quartz and mullite phase in the material, improve the chemical stability of the material, add anti-aluminum liquid wetting agent, improve the anti-aluminum liquid wettability of the material, add ultra-fine powder and water reducing agent, reduce the amount of water, thereby reducing the porosity of the product, improve the density.

The anti-seepage castable developed by our company adopts reasonable aluminum-silicon raw materials, introduces composite binding agent and special anti-seepage materials, and prevents the continuous infiltration of aluminum liquid into the castable. It has the characteristics of good strength, anti-seepage effect and convenient construction.

Key words:

Impervious castable

Product inquiry

Note: Please leave your phone number or E-mail and our professionals will contact you as soon as possible!

Related Products